Infinite ScanShark V5

Non-Contact Laser Scanning Portable CMM

The ScanShark Laser Scanning System is comprised of a seven-axis INFINITE 2.0 SC portable CMM, a ScanSharkTM laser scanning probe, PolyWorksTM software and laptop or desktop computer, all in one powerful turnkey package! 3D laser scanning allows inspection of parts with or without CAD models using a laser scanning probe to swiftly collect data.

Three configurations are available:

- Reverse-engineering via PolyWorks / Modeler

- Laser scanning inspection via PolyWorks / Inspector

- Inspection and reverse-engineering with PolyWorks / Modeler and Inspector

The ROMER seven-axis INFINITE 2.0 SC portable CMM, available in 6, 8, 9, 10 and 12 foot measuring envelopes, brings all the benefits of articulating arm measurement to laser scanning. Its versatility allows access to those difficult-to-reach locations on the inside, topside and underside of the work-piece - anywhere you need to scan.

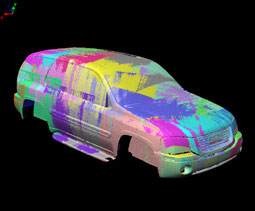

Laser scanning provides real-time surface inspection by comparing each point scanned with the laser probe to a CAD model in real-time. The system collects and analyzes more than 23,000 points per second for far more detailed inspection of both geometric and surface features than would be practical with a convention hard probe. A color gradient graphic indicates whether the points are in tolerance, above tolerance or below tolerance and instantly produces a color "weather map" of the points on the screen.

3D scanning also provides real-time geometric inspection by enabling scanning of features including circles, slots, square slots, rectangles, planes, spheres and cylinders in real-time at more thousands of points per second for fast, accurate and easy measurement. Much faster than hard probing, it gives you thousands of points to define a feature with precision!

A ROMER arm represents the ideal combination of an inspection system and a reverse-engineering system in a single platform. Often, a reverse-engineering system cannot be justified on that use alone; with a ROMER laser scanning system, you get both functions in one unit.

The INFINITE 2.0 portable CMMs offer the following exclusive features:

- TESA Kinematic Probes with Swiss made Bridge CMM Class connectors provide carbon fiber construction with automatic probe recognition. When changing probes, Kinematic probes save time by automatically identifying themselves to the software and by not requiring re-calibration. If you need to replace a tip, the probe can be easily re-calibrated in the field.

- SpinGrip these infinite-rotating grips at elbow and forearm provide two "approved" grip positions for better ergonomics and do not allow the user to stress the arm during use.

- Pistol Grip a redesigned ergonomic handle increases operator comfort and productivity.

- Probe Holster provides easy access and storage of Kinematic probes. Includes slots to snap-in 3 probes and the Kinematic key.

- Upgraded Wi-Fi Wireless Connectivity - the Wi-Fi connection between the arm and computer allows the operator to position the computer where it is most convenient without having to worry about PC cables (or any cables, for that matter, thanks to the Li-ION battery). INFINITE 2.0 arms have been upgraded from WIFI 802.11b to WIFI 802.11g, the standard for wireless device connectivity, which offers speeds many times faster and longer range (up to 200 ft - even through walls) than other technologies such as Bluetooth.

- Integrated Li-ION Battery and Environmentally Sealed Cover - the integrated Li-ION battery is ideal for on-site inspection or measurement when AC power is not available or where cables are a problem. Several hours of battery life are typical with continuous operation. The patent-pending environmentally sealed battery cover prevents contamination of the battery compartment and accidental dislodging of the battery.

- Infinite Rotation - INFINITE series arms feature ROMER's patented infinite rotation of the principal axes. This allows inspection of hard-to-reach areas and avoids damaging the arm against rotational hard stops.

- Zero-G Counterbalance - the integrated Zero-G counterbalance offsets the weight of the arm and probe, thereby reducing operator fatigue and allowing one-handed operation from any position. The counterbalance works equally well from any position in the arm's reach, above and below the midline, without any tendency for the arm to "flop" when used high or low. The counterbalance helps protect the arm from unintended crashes with table or part. Calibrated Length Standard - ROMER provides a NIST-traceable calibrated length standard with each arm to allow the operator to easily verify and document system performance for ISO or vendor requirements.

- Carbon Fiber Arms - all ROMER arm tubes are constructed of carbon fiber. Carbon fiber is 25 times more thermally stable than aluminum, thereby ensuring temperature stability in real-world use and rendering temperature compensation unnecessary. Under normal usage the carbon fiber tubes have a lifetime warranty.

- Quick Mounting - a unique quick-change mounting system requires no tools, allowing fast set-ups and providing a small footprint. The arm can be attached to many types of bases (fixed, magnetic and vacuum mount), tripods and Brunson stands for INFINITE flexibility of mounting.

- Heidenhain Encoders - Heidenhain, the worlds leading manufacturer of high-accuracy rotary encoders, builds custom "wide-track" encodes designed specifically for INFINITE 2.0 arms.

The ScanShark is available with either a V4ix laser scanning probe, capable of scanning 23,000 points per second or our premier V5 laser scanning probe.

The V5 is capable of scanning 458,400 points per second with a minimum point-to-point resolution of 12 microns. Additional features of the V5 include:

- Large field of view - 140 mm and 110 mm

- Projected rangefinder - projects accurate trapezoidal representation of field of view and optimal scanning offset distance - enabling users to ecome familiar with good scanning procedure.

- Dynamic range - captures accurate data on dark and reflective surfaces, negating the need for white powder sprays. Sensor is impervious to ambient light.

Both lightweight scanners (.75 lb) can rapidly capture large, geometrically complex areas with direct integration into your configuration of PolyWorks.

Benefits of SharkScan non-contact laser scanning:

- Non-contact laser scanning avoids marring of sensitive surfaces of deflection off thin or soft materials.

- Real-time inspection allows rapid identification of errors, allowing for quick correction.

- Ideal for generating point clouds for reverse engineering (via PolyWorks Modeler).