Alfred Lewis Engineering

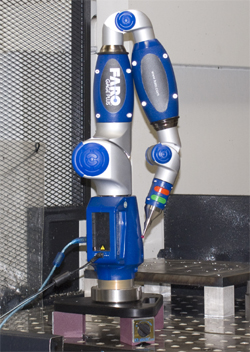

Alfred Lewis Engineering adopts the latest industry-standard FARO Gage measurement technology for machine shop flexibility, productivity and enhanced levels of customer service.

Alfred Lewis Engineering, based at Braeside, in Melbourne, was established in 1966, and is currently managed by its two business managers and operators - John Ellis and Greg Strahan.

Alfred Lewis Engineering, based at Braeside, in Melbourne, was established in 1966, and is currently managed by its two business managers and operators - John Ellis and Greg Strahan.

The strength of the company is its commitment to quality and ability to service the varied client base in both CNC and manual machining capacity. Customers include manufacturers of scientific instruments, industrial process equipment, transport accessories, aviation components, mining equipment and accessories, building equipment, machine tools, packaging machinery, printing machinery and company's requiring one off or prototype machining.

Since the first CNC machine was installed in 1981, a further eighteen CNC lathes and machining centres have been installed. The Company's commitment to accessing and applying the best available technology extends through all business areas.

Recently purchased items include a state-of-the-art FARO Gage coordinate measurement machine, multi-tasking auto loading CNC lathes and both vertical and horizontal multi-pallet CNC machining centres which demonstrate how Alfred Lewis is at the forefront of innovation. In addition to CNC machinery the company has a comprehensive manual machining section including deep hole and gun drilling.

Recently purchased items include a state-of-the-art FARO Gage coordinate measurement machine, multi-tasking auto loading CNC lathes and both vertical and horizontal multi-pallet CNC machining centres which demonstrate how Alfred Lewis is at the forefront of innovation. In addition to CNC machinery the company has a comprehensive manual machining section including deep hole and gun drilling.

Manufacturing operations run twenty-four hours a day, employing over thirty highly skilled programming, operators and support staff in a purpose built facility, occupying 2,200 square metres. "Our one-stop-shop offers services such as monthly or bimonthly deliveries to schedule, consignment stock facilities and management of post machining processes of heat-treatment, grinding, plating and assembly". Machining of many and various materials such as steels solid, cast and forged, stainless steels solid and castings, titanium, aluminium, brass, plastics and acrylics, cast iron solids and castings, tufnol and wood.

The growth of Alfred Lewis Engineering has resulted from developing "ongoing relationships with our clients, continued investment in the latest technology and a commitment to quality. The future will see the company continuing to build on these long term relationships, on the provision of additional services such as electronic ordering, expansion of consignment stock facilities and reducing turn-around time whilst maintaining 100 percent on-time-deliveries".

In order to sustain future growth and maintain our quality standards Alfred Lewis purchased a FARO Gage PLUS and rolling cart - a portable on-machine measuring system from Hi-Tech Metrology, in June 2008.

After installation and training on the FARO Gage, provided by Hi-Tech Metrology, and subsequent follow-up training the Alfred Lewis team has been able to achieve widespread usage of the portable measuring system around the workshop.

According to John Ellis, "the flexibility and portability of the FARO Gage, mounted on its own FARO granite table rolling cart, gives the ultimate flexibility with a multitude of measurement tasks spread around the workshop. This is one of the major benefits of purchasing a FARO Gage portable system from Hi-Tech Metrology".

John went on the say that by using the FARO Gage system, Alfred Lewis has complete compatibility with some of their larger clients who also operate FARO Gage measurement systems. The FARO Gage is available with an extensive range of low-cost interchangeable probes, which are locally manufactured. These accessories allow users to perform a wide variety of measurement tasks. Complex, difficult to access area measurement tasks can be performed quickly and efficiently.

The new FARO Gage system, together with in-process machine gauging now supplement the quality systems and metrology processes. According to John Ellis the future is more on-machine inspection with accurate, reliable and state-of-the-art measuring tools such as the portable FARO Gage coordinate measuring machine. With these tools comes increased productivity, empowerment of the machine shop and ensures a better quality outcome for Alfred Lewis and our clients alike.

The FARO Gage experience at Alfred Lewis has been significantly enhanced, comments John Ellis,"by the very professional support and after-sales service and backup given by Hi-Tech Metrology", FARO Australasia's distributor. "Any questions regarding the software or how to measure something in the shop using the FARO Gage, is a simple phone call to Hi-Tech gets us going quickly and without a fuss. The combination of FARO products and Hi-Tech's expertise will continue to help Alfred Lewis implement future improvements in our never ending quest for continuous improvement and excellence in customer service".