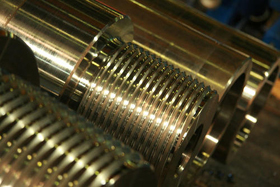

Drill Rod Threads

Silverise Increases Process Capability with a ScanArm and PolyWorks

Silverise is a Western Australian-owned company dedicated to providing quality drilling equipment and services to the global mining community. Along with supplying their customers with some of the best drill string components for raise bore, blast hole, water well and numerous other drilling applications they also distribute Indeco Australia rock breakers, pulverisers and compactors. Winners of the Western Australia Export Award in October 2009 in the Small to Medium Services Award category Silverise also provides drill rod inspection and repair services welding & fabrication, specialised fabrication and deep hole drilling.

THE PROBLEM:

The challenge for Silverise was to develop a more qualitative approach to measuring the internal and external thread forms of the boring rods. The raisebore drill rods are up to 380mm in diameter, 3 metres in length and threaded at both ends to mate with the adjoining drill rod.

The original measurement methods included the use of traditional thread gauges and hand-held profile gauges. The use of thread profile gauges however introduces inherent inaccuracies because of the thickness of the gauges themselves and the need to manufacture the profile introduces inaccuracies from the "true" thread design. Silverise in an effort to continuously improve their product quality of the drill rods and in order to better address customer concerns on quality, warranty returns and the need for better record keeping looked for a better solution.

THE SOLUTION:

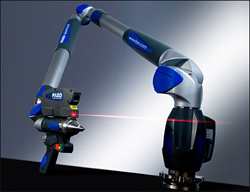

Silverise approached Hi-Tech Metrology in mid 2009 to help find an  improved measurement methodology to measure their key drill rod products, and with the assistance of the applications engineering team from Hi-Tech Metrology, a laser scanning solution was developed. The solution consisted of a laser scanning system - the Faro ScanArm with PolyWorks software to scan the external and internal thread profiles and compare the results, in real time, to 3D CAD models of the ideal parts. Scans are taken of the thread at a number of places around the drill rod in order to check for any potential variations in thread form, taper and size.

improved measurement methodology to measure their key drill rod products, and with the assistance of the applications engineering team from Hi-Tech Metrology, a laser scanning solution was developed. The solution consisted of a laser scanning system - the Faro ScanArm with PolyWorks software to scan the external and internal thread profiles and compare the results, in real time, to 3D CAD models of the ideal parts. Scans are taken of the thread at a number of places around the drill rod in order to check for any potential variations in thread form, taper and size.

Silverise' business partner and owner Rolf Bybyk comments on the solution from Hi-Tech Metrology by saying... "the laser scanning system takes out all of the guess work and uncertainty in our measurement process. We are now able to qualiatitively measure and retain the data within our systems of all of the drill rods we manufacture, saving us time and effort over our traditional methods."

The simplified "filing system" approach using PolyWorks software with advanced tools such as virtual profile gauging and cross-sectional best-fitting allows Silverise to improve product quality and productivity in their machine shop. Silverise are also able to now check their parts for concentricity and squareness with the built-in hard probe - features that they had not been ale to do in the past with their previous measurement techniques, and once again adding to improved product quality and significant benefits for their clients in terms of product reliability and performance.

RETURN ON INVESTMENT:

With the Faro ScanArm, PolyWorks software and our applications team Silverise are now able to capture and retain an accurate and repeatable record of the thread profile of all drill rods manufactured ensuring a significant improvement in product quality, reliability and warranty return costs etc. With measurement times now dramatically reduced and improved product quality the payback on the capital equipment investment has been, according again to Rolf Bybyk... "very quick, and pleasingly far sooner than initially estimated or expected."