Gear Inspection

It may not be widely known, but standard CMMs, when properly equipped, are the ideal flexible tool for measuring gears. They combine the flexiblity of a general purpose measuring system, with specialized probing and software that allows them to be fully functional gear measuring centers.

The Leitz product line has high accuracy machines, such as the PMM-F and PMM-G which are often used for high precision gear inspection. For more general purpose applications, a Brown & Sharpe Global CMM can also be equipped for gear measurement. Our software packages such as Quindos and PC-DMIS both have modules available specifically designed for inspecting gear geometry. Leitz scanning probes provide high density, high accuracy form data of the measured geometry.

The Leitz product line has high accuracy machines, such as the PMM-F and PMM-G which are often used for high precision gear inspection. For more general purpose applications, a Brown & Sharpe Global CMM can also be equipped for gear measurement. Our software packages such as Quindos and PC-DMIS both have modules available specifically designed for inspecting gear geometry. Leitz scanning probes provide high density, high accuracy form data of the measured geometry.

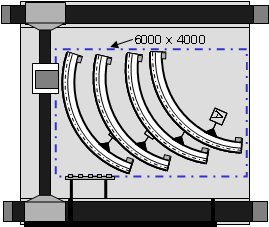

Companies in the windpower, heavy equipment, powertrain and power generation markets find that a Leitz CMM is ideally suited to the task of gear inspection, especially when the requirement is to measure extremely large gears or gear segments. Precise inspection of big gears has been traditionally quite expensive, if not downright impossible. This has all changed that with the introduction of the Leitz PMM-G series of high precision gear inspection centers. The PMM-G is available in several sizes: for gear diameters up to 2950mm / 116", up to 3950mm / 155" and up to 4450mm / 177". The shaft length can be as long as 7000mm / 275".

...no weight limit and no rotary table

Because our gear inspection systems work without requiring a rotary table, the weight of the gear is practically unlimited and does not influence the accuracy of the system. An alignment or centering of the gear is not required. Because no rotary table is necessary, it's possible to inspect multiple gears on the same table setup without interruption.

...measuring any kind of gear or cutting tool

With more than 25 years of experience in gear inspection we offer solutions for basically any kind of gear (cylindrical, spiral bevel, crown gears, helical gears, gear spurs, gear racks, gear segments). We can also precisely measure almost any type of gear cutting tool such as hob, shaper, shaver, broach and form cutter. Since 2008 even curvic couplings can be tested on Leitz machines. The measurement cycle itself, once programmed is fully automatic. The evaluation of the deviations can be done according to any common standard, such as AGMA, ANSI, ISO, DIN, JIS, CNOMO and CAT.

...segments and racks

Very large gears are manufactured in segments and quality control for those parts has always been an open issue. Where traditional dedicated gear testers encounter their limits the strengths of the PMM-G comes in. Due to its measurement principle, gear segments and racks are no problem for a Leitz PMM-G. After measuring the individual segments, the software can even put them together and evaluate pitch and runout of the gear.

...long shafts

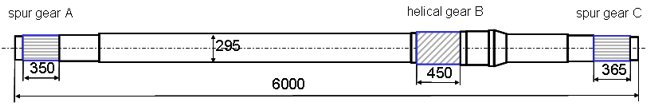

The Leitz PMM-G eventually solves the problem of measuring gears on long shafts. By fixing long shafts up to 7000mm / 275" horizontally, the PMM-G checks the gears and all features on the shaft fast, precise and fully automatic within a single set up.

....unique in its class

Due to the high demand from the world's leading producers of big gears, in particular from the fast growing wind power industry has resulted in the developement of these systems especially for large gears. The PMM-G's recent redesign was driven in part specifically in reponse to the needs of the gear industry, and is now unique not just in its ability to measure the largest gears made, but also prismatic parts such as gear boxes on the very same device.

|

|