Productivity Benefits in Plastic Component Sector

Management at W&S Plastics, in Sydney are strong believers in the use of the latest range of measurement technologies for sustainable process improvement and productivity benefits within their business.

W&S Plastics, a successful plastic injection moulding business in Sydney's western suburbs, runs 24-hours per day 7-days per week making complex plastic mouldings and components for the bio-medical, industrial and telecommunications industry sectors. They are using the latest vision-based metrology products, such as the Micro Vu Vertex system, to help provide the impetus for continuous improvement for the business.

With 30 plus plastic injection moulding machines in its Sydney operation, 10 pad printing machines, 20 robots and six ultra-sonic welding machines, W&S Plastics is able to manufacture a wide range of complex plastic components in a huge range of latest engineering-grade plastics.

Clients such as Resmed, Cochlear and Ventracor in the bio-medical field rely on the quality of the components supplied by W&S Plastics to ensure that their own products meet the critical needs of clients and patients in need of assistance through new technological bio-medical devices such as sleep apnea masks, bionic implants and components for heart pumps etc.

Some 5-years ago W&S Plastics purchased their first Micro Vu vision-based metrology system from Hi-Tech Metrology and, when production demands increased last year, again W&S Plastics turned to Hi-Tech Metrology for assistance on additional inspection and metrology equipment for the business.

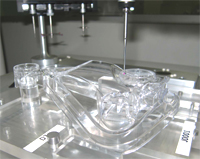

After careful evaluation W&S decided to purchase another Micro Vu Vertex automatic vision-based measurement system, but this time chose to include an optional touch-probe system with the installation. This gives W&S the ability to combine both touch probe and non contact vision measurement on components that are either difficult or time consuming to measure with just the standard video-camera system.

The two Micro Vu machines are now being used both for quality control as well as for first-offs and PPAP / OTS reports for clients and for new projects and components in W&S's metrology department.

According to W&S Managing Director Andrew Wiseman, "with the Micro Vu machines, the main productivity benefit has been that we are now able to check more difficult to measure dimensions quickly and with more accuracy than we have ever been able to do in the past.." "Our operators are able to measure and assure their own parts and process using the Micro Vu machines, ensuring that our clients only get good parts."

Further productivity gains are being made by W&S Plastics moving a number of the quality control checks onto the second and newer Micro Vu machine, in order to find any production problems with process quality sooner and before the moulding process goes out of control, through the use of run charts and other SPC methods employed by the business.