Redmond Repetition

Redmond Repetition Engineers was started almost 30-years ago in June 1981 by local business identity John Redmond in his suburban back-yard in Melbourne and now has grown to become a TS 16149 certified business employing 38 people across two-shifts in their modern and purpose-built 4,000 square metre facility.

Redmond Repetition Engineers was started almost 30-years ago in June 1981 by local business identity John Redmond in his suburban back-yard in Melbourne and now has grown to become a TS 16149 certified business employing 38 people across two-shifts in their modern and purpose-built 4,000 square metre facility.

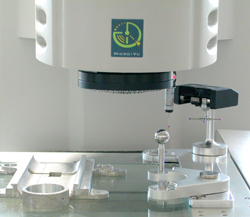

Late 2009 John Redmond saw the need to invest in the latest vision-based dimensional metrology product, the Micro-Vu Vertex, in order to assure the quality of their aerospace components about to be sent overseas for critical defence and government contracts.

Over the past seven to eight years the business has invested over $8 million in new equipement and now produces precision components for some of the biggest global brands in industry sectors such as Military, Medical, Aviation and Automotive with exports to the USA, UK, Poland and Asia. Clients have come to trust and respect the capability and commitment every job is given. It's the peace of mind, the strong relationships, the personal touch and the solid commitment to getting the job right first time that keeps clients coming back.

RRE are not only able to produce large run sizes of parts but, due to a significant amount of work that has been able to done internally with the reduction in set-up times, are able to offer run sizes down to as low as 50 pieces - making the business very flexible and responsive to the needs of both their domestic and export customers.

In late 2010 after many discussions with Hi-Tech Metrology and in consultation with other members of the ART export network who already owned and used Micro-Vu in their businesses, John Redmond took the decision to purchase the Micro-Vu Vertex 420.

In purchasing the Vertex video-based measuring machine and add-on 4-port touch trigger probing system, John Redmond commented that..."we have a clear objective to only invest in the latest and leading edge technologies and our investment in this equipment is in line with this guiding principal. Our objectives with the Micro-Vu equipment purchase have been to:

- Obtain measurement repeatability for all current parts and become 100% confident in our processes and capabilities;

- Completely satisfying our export customers; and

- To be able to measure complex and intricate parts - that can't be measured in any other way"

RRE continue to improve their internal systems and are applying the capabilities of the Micro-Vu equipment to more and more of their products. According to both John Redmond and general manager Paul Rafferty they have clear objectives over the next 12-months to use this equipment for rapid and efficient measurement of all their parts and to have all personnel professionally trained on the use and programming the system.

RRE continue to improve their internal systems and are applying the capabilities of the Micro-Vu equipment to more and more of their products. According to both John Redmond and general manager Paul Rafferty they have clear objectives over the next 12-months to use this equipment for rapid and efficient measurement of all their parts and to have all personnel professionally trained on the use and programming the system.

Hi-Tech Metrology is providing further on-going assistance and support to RRE and are offering additional tailored training programs for equipment operators as well as skills enhancement courses and on-the-job training for advanced programming techniques tailored to RRE's more complex array of components.

Senior management at RRE are very pleased with their Micro-Vu purchase and see it now as an integral part of their 3-5 year vision for the business as a state-of-the-art CNC facility able to produce both short run quantities as well as large runs competitively, and with more and more focus on export growth in particular in the rapidly growing regions of southeast Asia for automotive, aerospace and defence projects.