Austech 2013

This year on stand #646 we will be displaying the latest advances in 3D scanning, inspection and reverse engineering from 7 to 10 May 2013 at the Melbourne Exhibition Centre. To register for this not to be missed event simply click here and fill out the online form.

Whether you use 3D scanning technology for design, analysis or inspection, this is the event not to be missed! With a focus on using the latest scanning technology to capture and process high resolution 3D spatial geometries for reverse engineering, visitors will walk away with practical knowledge and information on a complete range of laser scanning technologies that are available today, and gain an understanding of the key benefits that they can expect to achieve with the adoption of new technology in their day-to-day business operations.

Whether you use 3D scanning technology for design, analysis or inspection, this is the event not to be missed! With a focus on using the latest scanning technology to capture and process high resolution 3D spatial geometries for reverse engineering, visitors will walk away with practical knowledge and information on a complete range of laser scanning technologies that are available today, and gain an understanding of the key benefits that they can expect to achieve with the adoption of new technology in their day-to-day business operations.

A combination of hands-on live demonstrations of the latest metrology equipment available today and interactive, problem-solving discussions will bring together industry professionals and the Hi-Tech Metrology team to give Australia's manufacturers the best information available.

Our display on stand 646 will feature 3D scanning and inspection technology from Hexagon Metrology, Romer, Brown & Sharpe, Leica, Perceptron and Micro-Vu. We see the Austech show as a great opportunity to introduce the benefits and latest developments in 3D scanning technologies for inspection and reverse engineering to the Australian advanced manufacturing industry and will show how these technologies help manufactures produce better designs, and get new products to market faster.

Our display on stand 646 will feature 3D scanning and inspection technology from Hexagon Metrology, Romer, Brown & Sharpe, Leica, Perceptron and Micro-Vu. We see the Austech show as a great opportunity to introduce the benefits and latest developments in 3D scanning technologies for inspection and reverse engineering to the Australian advanced manufacturing industry and will show how these technologies help manufactures produce better designs, and get new products to market faster.

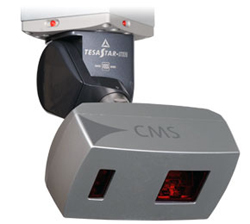

One of the highlights on display will be the Brown & Sharpe Global Performance 7107 CMM fitted with the fully integrated Hexagon Metrology CMS106 laser scanner. This next generation of scanning probe is ideally suited to the measurement of complex freeform parts where the shape is not easily represented by simple prismatic entities, examples being car, aerospace, motorcycle bodies, trim and seats; many consumer products, medical components and blade shapes such as used for power generation.

Other key equipment on show this year includes: Romer Absolute 7325SI in action, scanning a range of complex parts and components for reverse engineering and inspection tasks. The Romer Absolute SI scanning solution is the latest release product from Hexagon Metrology's portable arm business, Romer Inc., and represents the latest development of a fully-integrated laser scanning system on the highly accurate and ground-breaking new Absolute series of portable measuring arms. The integrated laser scanner technology is a milestone in the world of portable CMMs, with the new system our customers can easily achieve accurate and meaningful measurement results while benefiting from the Romer Absolute arm's mobility and efficiency.

Romer Absolute 7325SI in action, scanning a range of complex parts and components for reverse engineering and inspection tasks. The Romer Absolute SI scanning solution is the latest release product from Hexagon Metrology's portable arm business, Romer Inc., and represents the latest development of a fully-integrated laser scanning system on the highly accurate and ground-breaking new Absolute series of portable measuring arms. The integrated laser scanner technology is a milestone in the world of portable CMMs, with the new system our customers can easily achieve accurate and meaningful measurement results while benefiting from the Romer Absolute arm's mobility and efficiency.

Romer Absolute 7325SE on a Brunson carbon-fibre lightweight tripod fitted with a high end laser scanner designed for complex and difficult reverse engineering and inspection projects. The Romer Absolute SE series gives users the ability to specify and mount virtually any laser scanning system to the arm. Laser scanners supported by the SE series Absolute arms include Hexagon's own CMS, Perceptron's range of ScanWorks scanners, Kreon scanners, and many more thus enabling us to tailor the right solution for each and every application.

Vertex vision-based inspection system from US-manufacturer Micro-Vu which is excellent for measuring small and delicate parts, and has found many uses in the Australian market in the precision engineering, electronics, and plastic injection moulding sectors.

Vertex vision-based inspection system from US-manufacturer Micro-Vu which is excellent for measuring small and delicate parts, and has found many uses in the Australian market in the precision engineering, electronics, and plastic injection moulding sectors.

Leic a AT401 laser tracker which has taken the market by storm. The AT401 is the smallest and the most compact laser tracker on the market - yet still capable of measuring distances up to 160 metres with incredible accuracy and repeatability.

a AT401 laser tracker which has taken the market by storm. The AT401 is the smallest and the most compact laser tracker on the market - yet still capable of measuring distances up to 160 metres with incredible accuracy and repeatability.