ShapeGrabber - Automated 3D laser scanning for inspection

Measuring complex shapes is ShapeGrabber's specialty. They design and manufacture industrial 3D laser scanner products that are ideal for measuring complex shapes such as injection moulded plastics and castings that are otherwise too time consuming, costly, or difficult to measure.

ShapeGrabber's state-of-the-art inspection solutions are the next generation in optical 3D measurement systems. Considered to be one of the industrial pioneers in the field, ShapeGrabber has been supplying 3D scanners to industrial customers for more than a decade and now these systems are available in Australia from Hi-Tech Metrology, the leaders in metrology and inspection innovation.

ShapeGrabber 3D scanners are used by customers in the automotive, aerospace, medical, and other industries for quality inspection, dimensional troubleshooting, design and modelling.

ShapeGrabber systems require a fraction of the time and resources compared to CMM systems while providing NIST-traceable full surface data of even the most complex plastic injection moulded parts, stampings, castings and more.

Their 3D scanners help manufacturers to dramatically reduce inspection costs, improve product quality, rapidly conduct first-article inspection, quickly troubleshoot fit problems, and provide documented proof that they are meeting specifications. ShapeGrabber systems are turnkey solutions that include all required hardware, software, CAD workstation, installation, training, and a full year of support. ShapeGrabber continues to pioneer innovation in 3D measurement focusing on ever-greater accuracy, system flexibility, ease of use, and speed.

ShapeGrabber systems are turnkey solutions that include all required hardware, software, CAD workstation, installation, training, and a full year of support. ShapeGrabber continues to pioneer innovation in 3D measurement focusing on ever-greater accuracy, system flexibility, ease of use, and speed.

"ShapeGrabber currently offers a range of four different groups of products - from automated 3D scanning systems, classic 3D scanners, portable 3D scanners and 3D scan heads but it is our innovative range of automated 3D scanning systems that we feel will offer the greatest benefit to our clients in Australia through Hi-Tech Metrology..." comments Pierre Aubrey.

"We see Hi-Tech Metrology as our ideal partner in Australia, Aubrey goes on to say, after first meeting them in Canada at a PolyWorks User's Meeting in 2007 and we always knew that we would find an opportunity to work together with Hi-Tech and we are pleased that this opportunity has now presented itself. Hi-Tech Metrology's reach in the metrology space as Australia's largest specialist equipment supplier is impressive and is a key reason why we chose to partner with them comments Aubrey."

With the growing interest in the Australian market for 3D laser scanning systems for both inspection and reverse engineering tasks the current hardware options are varied but primarily they are heavily biased towards manual systems - such as portable measuring arms. "Whilst arm-based solutions these days are very good and ideal for in-field inspection and reverse engineering applications, with the ShapeGrabber automated solution, comments Hi-Tech Metrology's general manager David Eldridge, we have an opportunity to present to customers who have medium or high volume inspection process requirements, a solution that enables more repeatable and accurate results to be achieved than ever before". We see the automated 3D laser scanning solutions offered by the ShapeGrabber product line as being an ideal step for manufacturers of castings, forgings and plastic moulded parts and panels to achieve rapid throughput through their inspection process with a fully-automated measurement and reporting process. These processes coupled with the use of advanced 3D point cloud inspection software - such as PolyWorks/Inspector, allows customers to measure their parts automatically to a 3D CAD model and report both graphically as well as numerically on the conformance or otherwise of the parts being produced.

We see the automated 3D laser scanning solutions offered by the ShapeGrabber product line as being an ideal step for manufacturers of castings, forgings and plastic moulded parts and panels to achieve rapid throughput through their inspection process with a fully-automated measurement and reporting process. These processes coupled with the use of advanced 3D point cloud inspection software - such as PolyWorks/Inspector, allows customers to measure their parts automatically to a 3D CAD model and report both graphically as well as numerically on the conformance or otherwise of the parts being produced.

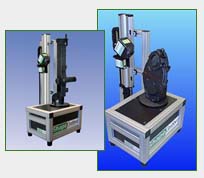

ShapeGrabber offer two models in their enclosed automated model systems the Ai310 - a workbench or a standard inspection table with a scan volume of a cylinder 300mm in height and 200mm in diameter to the Ai810 with its 800mm of vertical rail movement and 1,250mm of horizontal movement and a high precision rotary table.

Another two models are available the Ai300 and Ai600 with an "open" design where this type of arrangement is more suitable for customers parts or the measurement environment. Again with 300mm or 600mm of vertical travel and the ability to measure objects up to 200mm in diameter at between 18,000 - 100,000 points per second, this system is ideal for measuring parts such as plastic mouldings close to the production line when a quick and flexible inspection process - with minimal CAD skills from the operators, can produce go/no-go results and reports so that production can made the right decisions on the process in the most expeditious manner possible.

Hi-Tech Metrology is very pleased to be able to offer another high quality range of products to our already significant product portfolio and a product range that not only offers customers the potential for significant time savings but also allows for better flexibility and higher levels of repeatability never possible previously without using CMM equipment. We believe that ShapeGrabber will be a significant entrant into the Australian market one that potentially may change the 3D laser scanning and inspection landscape forever.