TubeInspect P8

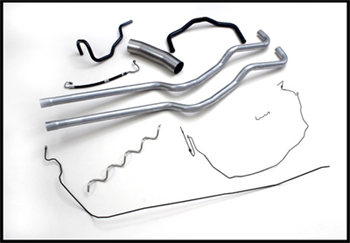

Most of all bent tubes and wires are less than 1,000 mm long from end to end and have a maximum diameter of 100 mm. The first model of the new TubeInspect generation, the TubeInspect P8, was especially developed for the efficient quality control of this kind of component.

Equipped with 8 high-resolution cameras, TubeInspect P8 is suitable for tubes and wires with diameters from 1 mm to 125 mm and allows for optimum 3D inspection of objects of up to 1 m length. However, even longer objects can be measured with TubeInspect P8. The lateral doors allow for an overlapping repositioning section by section.

Sheath tolerance can be determined to an accuracy of up to 0.035 mm. Measuring results are provided within 2 to 5 seconds. Considerably optimised production processes, e.g. the setup of bending machines, save time and costs. Combined with the software platform BendingStudio, the system offers various application-oriented functionalities.

Thanks to state-of-the-art technology, TubeInspect P8 fulfills highest requirements regarding accuracy and speed. The long-life and low-maintenance LED illumination technology guarantees a particularly smooth illumination of the measuring field.

High-resolution cameras with latest GigE technology ensure an almost synchronic capture of the measuring object within milliseconds. The innovative three-dimensional glass reference is highly precise and long-term stable.

TubeInspect P8 fits onto a euro-pallet. The result: reduced transport costs and floor space in operation. TubeInspect P8 is applicable for mobile use in production environment. The system is insensitive to vibrations; after change of location, TubeInspect P8 is immediately usable, without new calibration.

| Request More Information | Product Brochure |