DOCS software

Enhance your tube shop productivity

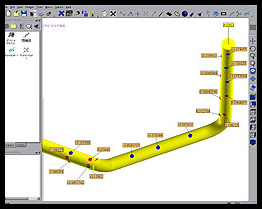

ROMER DOCS is the premier CAD-based tube inspection software. Designed to revolutionize quality control in the tubing industry, DOCS stands for Data Overlay Camera System and is compatible with ROMER portable measuring arms.

DOCS can inspect and measure round metallic and non-metallic wire, tubing, and piping used in almost any industry - automotive, aerospace, shipbuilding, medical, machinery, appliance, and more. DOCS can also produce corrected bend data for CNC tube benders.

Full CAD Capability

- Extraction of tube data from CAD - a unique process to capture tube data from CAD.

- Extraction of geometry from tubes - users can break a tube file down into individual geometric entities for easy manipulation.

- Ability to group multiple tubes in one part file - this keeps all parts of a tube assembly in one file.

- Tube measurement plus geometry measurement in ONE software - eliminating the need to run multiple applications if your tube has brackets, flanges, bosses or other geometric features to be measured.

Tube Measuring Productivity Features

- Auto Single Measure Mode automates the tube inspection process by minimizing operator input requirements.

- Surface inspection with contact or non-contact tube probes - inspect all parts of the tube including bends, brackets and flanges.

- Use hard probes and non-contact tube probes interchangeably during the measurement cycle

- Real-time surface inspection - provides the ability to locate brackets and flanges on a tube.

- Calculation of End-to-End length and its error

- Hard point fit alignment

Tube Fixture Measurement

- Easily Measure existing tube fixtures for accuracy

- Reverse engineer the tube shape out of an existing fixture

Reporting

- DOCS overlays inspection geometry onto digital photos of the part for unprecedented ease in visualizing the part set-up and context. This Transprojection function is enabled if your ROMER portable CMM is equipped with a digital camera (INFINITE series 1 and later).

- Easily modified HTML reporting capability for clear, informative reporting.

Available Editions

- DOCS with multiple language support: English, Chinese (simplified), Czech, German, Spanish, Italian, Japanese, Polish, and Turkish.

- DOCS Offline for programming tubes from CAD without using the portable CMM.

- Tube Bender Interfaces for direct communication with tube bending machines (see next section)

Eliminate Waste in Tube Bending with a Portable CMM and DOCS

As tube inspection goes hand in hand with bending, DOCS can send corrected bend data directly to the CNC tue bender with the Tube Shop Manager module. This process eliminates costly data transcription errors, and enables correction of bend data based on inspection results of the first tube bent. The second tube is usually in spec and ready to ship without wasting hours adjusting the bender trying to make a good tube. The elimination of waste and scrap, as well as increased shop productivity, is a key benefit of a ROMER arm system with DOCS and Tube Shop Manager.

| Request More Information |