PolyWorks

Inspection & Dimensional control

This conclusion is often heard in industrial metrology circles. Why? Because InnovMetric invented point-cloud-based dimensional inspection. And now the PolyWorks dimensional control platform is available not only for all high-density point cloud 3D digitizing platforms, but also for all major brands of articulated arms, photogrammetry based and hand-held probing devices, laser trackers, and manual CMMs.

Point cloud engineering

Point cloud engineering

Discover why major automotive and aerospace OEMs around the world rely on the PolyWorks platform for tool and assembly engineering. From your computer, virtually assemble digitized product components, identify and characterize interfering parts, or highlight instabilities in your tool design or assembly process.

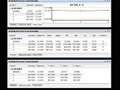

Statistical process control (SPC)

Statistical process control (SPC)

PolyWorks offers you an embedded statistical process control (SPC) methodology, ideal to quickly and easily analyze multiple digitized instances of a part or product in a pre-production context. You can now digitize or probe a set of pieces, accumulate measurement results as pieces are being analyzed, and then visualize a trend chart, Cp, or Cpk for nearly all dimensions.

Reverse engineering

Reverse engineering

You care for efficiency and want to build real CAD models of digitized objects. Why not leverage your existing CAD modeler? We firmly believe that CAD modeling is best performed in your corporate CAD system which is why PolyWorks' reverse engineering philosophy consists in optimally extracting CAD entities (such as curves, surfaces, sketches, or prismatic features) on digitized models, to serve as a starting point in your corporate CAD modeling solution.

Polygonal manufacturing

Polygonal manufacturing

Top polygonal quality is at the core of PolyWorks' success. With its unmatched adaptive point cloud meshing technology and capability to reconstruct perfect geometry from imperfectly digitized parts, PolyWorks has dramatically expanded the use of polygonal models (STL) in industrial applications, enabling remarkable new applications, such as aerodynamic simulation on digitized clay models or mold and die duplication from polygons.

Finite element meshing

Finite element meshing

A dream has now become reality. You can now create quadrilateral meshes of digitized parts for finite element analysis software, without having to edit polygonal models or fit NURBS surfaces. Ten times faster than any other comparable workflow, the PolyWorks solution morphs CAD models onto digitized polygons to create perfect models in a wink.

Airfoil gauging

Designed and tested in collaboration with market-leading global airfoil manufacturers, the PolyWorks Airfoil Gauge module offers you a toolbox dedicated to controlling airfoil dimensions at various stages of the manufacturing process.

Fixture & jig building

PolyWorks delivers the most flexible toolbox to build fixtures and jigs using tactile probing devices. In addition to supporting more traditional workflows where operators build to tooling points in real time, PolyWorks fully supports the capability of directly building to part or tool CAD models. With a minimum of clicks, operators can predefine feature characteristics to be built, configure the probe tip compensation, and define tolerances.

| Request More Information | Product Brochure | |||