ShapeGrabber

Automated 3D laser scanning for inspection

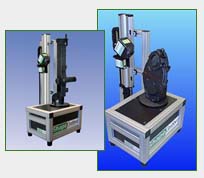

ShapeGrabber's Ai Series automated 3D laser scanners can bring speed, accuracy, ease-of-use and complete coverage to industrial 3D inspection. Using multiple motion axes, ShapeGrabber laser scanners eliminate the need for software alignment and registration and ensure fast, accurate results. These automated laser scanning solutions are ideal for situations in which speed and ease of use are important.

ShapeGrabber Ai310 features & Benefits

- Very fast: reduce your inspection time to minutes instead of hour.

- Turnkey: all you need is your part

- Totally integrated: acquire, align, and inspect using a click of the mouse

- Compatible with a wide variety of materials and colors

- Works in all normal lighting conditions

- Easy to use: requires no software alignment

- 300mm (12") of vertical motion

- High precision rotary table automatically reorients part being scanned a full 360 degrees

- Scan volume: Cylinder of 300mm (12") height X 200mm (8") Diameter

- From 18,000 to 100,000+ points/sec

ShapeGrabber Ai810 features & Benefits

ShapeGrabber Ai810 features & Benefits

- Performs automated inspection in minutes as opposed to hour

- Integrates the acquisition, auto alignment and inspection process

- Offers GD&T reports

- Provides full 3D quality control

- Includes Go/No Go capability

- Compatible with a wide variety of materials and colors

- Works in all normal lighting conditions

- Creates digital inspection reports that can be saved and shared

- Reduce inspection time by up to 95% (when compared with a CMM inspection)

- Improve production efficiency

- Reduce equipment downtime

- Reduce material waste

- Reduce human inspection error

- Increase customer retention by shipping fewer defects

- Increase customer satisfaction by providing proof that specs are met

ShapeGrabber Ai300 and Ai600

- Very fast: reduce your inspection time to minutes instead of hours

- Turnkey: all you need is your part

- Totally integrated: acquire, align, and inspect using a click of the mouse

- Compatible with a wide variety of materials and colors

- Works in all normal lighting conditions

- Easy to use: requires no software alignment

- Vertical motion: 300mm (12") for Ai300, 600mm( 24") for Ai600

- High precision rotary table automatically reorients part being scanned a full 360 degrees

- Scan volume: Cylinder of 300mm (12") height X 200mm (8") Diameter (Ai300)

- Scan volume: Cylinder of 600mm (24") height X 200mm (8") Diameter (Ai600)

- From 18,000 to 100,000+ points/sec